Water Reuse Techniques Adopted by Water-Scarce States

SF Non-Potable Reuse Required

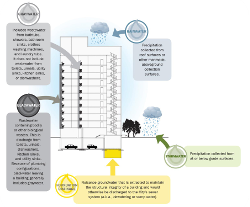

New buildings in San Francisco larger than 250,000 sq ft are now required to install and operate an onsite non-potable water system to treat and reuse graywater, rainwater and foundation drainage for toilet flushing and irrigation.

Full Image

San Francisco On-Site Water Reuse

Buildings have the potential to use stormwater, graywater, blackwater and groundwater that accumulates around the foundation for "on-site" toilet flushing, planting and grounds watering, and aesthetic water features. In 2012, the City and County of San Francisco made it possible for for commercial, multi-family and mixed used developments to use alternate sources of water for non-potable applications.

More Information

Orange County California's Groundwater Replenishment System

Beginning in the 1970s, Orange County California began injecting highly treated wastewater into its groundwater aquifer as a barrier to Pacific ocean saltwater intrusion, which was threatening its drinking water supply (See the left-hand side of the diagram below). In the following decades, Orange County gained a lot of experience with being able to reliable treat its wastewater to very high quality.

Based on this experience, the County is now going beyond injecting wastewater to block saltwater intrusion. It is now replenishing its groundwater aquifer for indirect potable reuse. That is to say, recycled water filters through the ground, mixes with existing groundwater, and is used for drinking water.

The County has developed a "locally-controlled, drought-proof and reliable supply of high-quality water in an environmentally sensitive and economical manner." This groundwater replenishment system uses half the energy needed to bring water to the Los Angeles area from Northern California. It decreases the water demand and environmental impacts on the Sacramento San Joaquin Delta, draining to the Northern San Francisco Bay, and the Colorado River.

More Information

Orange County Groundwater Recharge Diagrams

Orange County Groundwater Recharge Diagrams

Clever Ways Water is Being Reused: Case Studies

Emory University WaterHub On-site Water Reuse Treatment Greenhouse

Emory University WaterHub On-site Water Reuse Treatment Greenhouse

Emory University On-Site Sewage Treatment and Reuse

The first system of its kind installed in the United States, the WaterHub® is a decentralized, commercial-scale water reclamation and reuse system serving Emory University’s main campus just outside of Atlanta, GA. Capable of recycling up to 400,000 gallons-per-day, nearly 40% of Emory’s total campus water needs, the WaterHub mines wastewater directly from the campus sewer system and utilizes ecological treatment processes to treat the wastewater for beneficial reuse.

Between the WaterHub’s commissioning in May 2015 and January 2018, the WaterHub has processed over 160 million gallons of water. Treated reclaimed water is used to supply process make-up water at five chillers, the campus steam plant and toilet flushing. This redundant supply of reclaimed water has resulted in over 95% displacement of potable water in campus utilities. The WaterHub includes a 50,000 gallon emergency water reserve, which allow Emory’s heating and cooling systems to function for an average of seven hours, depending on seasonal operating demands, in the event of any disruption in water availability.

Emory University WaterHub Hydroponic Treatment Greenhouse

Emory University WaterHub Hydroponic Treatment Greenhouse

By harvesting wastewater flows from overburdened sewer lines, the WaterHub reduces the load on municipal infrastructure effectively extending its useful life and reducing the impacts of infrastructure failures. This was put to the test in July 2015 when a 48” potable water main break occurred just outside of Emory’s campus. More than 700,000 lived through a 3-day water boil advisory, while DeKalb Medical Center had to cancel all surgeries, and the Center for Disease Control and Prevention’s main campus was forced to close. During this time, the WaterHub served all of Emory’s critical HVAC equipment, with no interruption or pressure loss in campus steam and chiller plants. The reduced demand for potable water and the deployed reclamation strategy helped mitigate a water management crisis on Emory’s campus.

The WaterHub also addresses the challenges associated with energy consumption. Commonly known as the water-energy nexus, traditional water and wastewater treatment systems are highly mechanized, requiring miles of distribution piping. As a result, traditional treatment systems consume vast quantities of energy. Since the WaterHub is an on-site ecologically based treatment system, it removes the need for highly mechanized and energy dependent treatment systems and extensive distribution systems. In 2017 alone, Emory’s WaterHub directly saved the University over 172,000 kWh and reduced the University’s greenhouse gas emissions by 121 tons of CO2.

Lower wetland treatment cells of the Emory University WaterHub water reuse system

Lower wetland treatment cells of the Emory University WaterHub water reuse system

In addition to its functional use as a water reclamation facility, the WaterHub is designed as a living, learning laboratory to enhance the University’s academic environment. With built-in lab space and easy access ports for water quality testing, the facility enables research in a number of disciplines and is used as an immersion learning tool to enhance curriculum. Emory’s faculty have integrated new curriculum into the facility, and the WaterHub is expected to bring additional research funds and enable the University to qualify for new grants in the future.

The WaterHub was made possible by an innovative water purchase agreement between Emory University and Sustainable Water, a leading provider of water reclamation technology. The WaterHub creates lower cost water at a long-term stable rate and will produce millions of dollars in water utility savings over a 20 year period. To learn more about the WaterHub at Emory University and the benefits of on-site water reclamation and reuse, including a brief video, click here.

Craft Breweries Discover Water Reuse

Over 5,300 craft breweries were operating in 2016, producing 24.6 million barrels that year with a retail value of over $23 billion according to the Brewers Association statistics. Because beer production uses about 7 gallons of water for every gallon of beer, brewers have a lot of fresh water and process water to contend with. Furthermore, the leftover process water typically needs to be pre-treated before it is sent down the drain to a municipal treatment plant. In some cases craft brewers have to truck their process water to treatment plants that are tens of miles away. This is not only costly, but also adds traffic to local roads, burns a lot of diesel fuel, and increases greenhouse gas emissions.

One innovative solution to all of these challenges, being used by Lagunitas Brewing Company in California and nine other breweries and wineries across the United States, is a suite of modular, on-site process water treatment technologies by Cambrian Innovation. In addition to treating process water, Cambrian’s EcoVolt product suit generates high quality biogas that can be used for onsite heat and electricity, and recycles water. The recycled water is typically used for non-contact processes such as rinsing and boiler maker-up; however, the advanced treatment technologies offered by Cambrian Innovation and similar firms can recycle water for use in brewing beer, if partners are interested in doing so.

Cambrian EcoVolt Water Treatment & Energy Generation System Delivery to Lagunitas Brewery

Cambrian EcoVolt Water Treatment & Energy Generation System Delivery to Lagunitas Brewery

Cambrian Innovation offers its entire EcoVolt product suite as a service, under the WEPA (Water-Energy Purchase Agreement) services. Read More.

Several breweries have already recycled process water (technically graywater) for direct potable reuse. Seismic Brewing Company, one of Cambrian Innovation’s partners, brewed a beer with water recycled by their EcoVolt MINI for last year’s California Craft Beer Summit & Festival. An affiliate of Half Moon Bay Brewing Company, located near the famous Mavericks big wave surf spot, produced a version of its Mavericks Tunnel Vision using recycled wastewater supplied by NASA. In 2015, the beer passed a blind taste test held at an international sustainability conference to promote the importance of wastewater reuse.

More Information

For examples of water reuse success stories closer to home, in Maryland,Read More

Emerging Technologies for Potential Use in the Future

Keep it Simple

New technologies don't need to be complex. Simple solutions tend to be inexpensive, and easier to implement and maintain. As a result, they are more likely to be adopted.

Iron and Sand Filters for Small Scale Water Treatment

Researchers with the CONSERVE Center are implementing and evaluating water filters that use sand and zero valent iron (ZVI). The field-scale research is being tested on recycled and surface waters from that are judged to be of poor microbiological, chemical or physical quality. Like a magnet, initial results suggest that the positively charged iron ions (Fe++) grab onto and effectively remove negatively charged chemicals, microbes and physical contaminants. Aside from initial effective results, the technology is promising in large part due to its simplicity.

Up Next: Maryland's Reuse Initiative

Although Maryland is a water rich state, leaders recognize the need to expand future options. We can anticipate population growth and water uncertainties due to climate change and potential emerging water quality issues. These new option are only available to us if we invest in gaining experience with water reuse technologies and management systems. For these reasons, Maryland is undertaking a water reuse initiative.

Learn more about Maryland's Water Reuse Initiative. (Next Page)

Contact Information

Please direct questions or comments to Jim George.